Picture this: deep in the humming heart of a cutting-edge robotics lab, a delicate robotic arm is performing micro-surgery. Its movements are impossibly smooth, utterly precise, stopping exactly where commanded without a hint of overshoot or vibration. Or imagine a high-speed packaging line, filled with whirring spindles winding ultra-fine wire or thread at breakneck speeds, the tension controlled with unwavering consistency, product after perfect product. Or perhaps envision a rigorous test bench for aerospace components, subjecting parts to millions of precise, repeatable cycles, simulating years of wear in days. What unsung hero makes such feats of engineering finesse possible? Often, it's the remarkably elegant yet frequently overlooked **Hysteresis Brake**.

Forget everything you think you know about traditional brakes – the screech of pads, the grind of gears, the inevitable wear and tear. Hysteresis brakes operate on an entirely different, almost magical principle: the power of magnetism. They harness a fundamental physical phenomenon to deliver control that’s smoother, quieter, and far more precise than their mechanical counterparts could ever dream of. It’s not brute force; it’s intelligent, frictionless mastery.

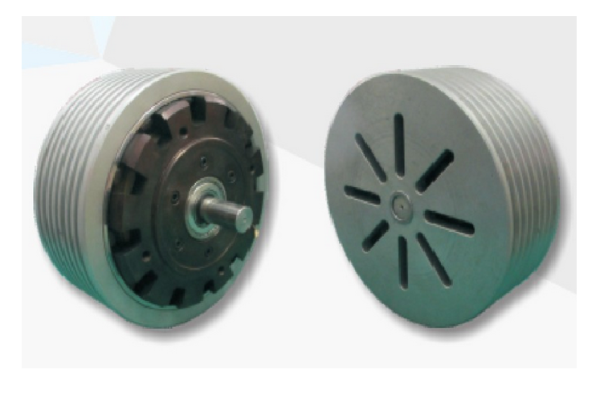

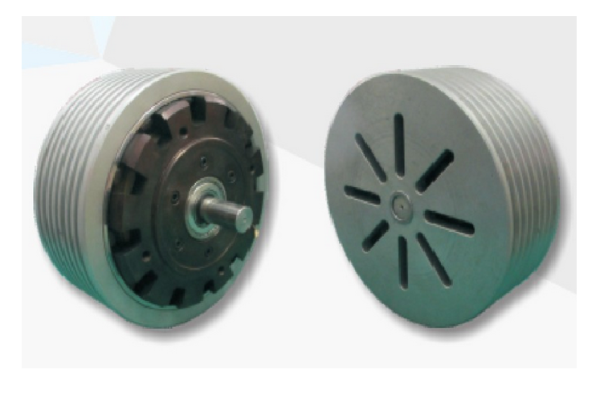

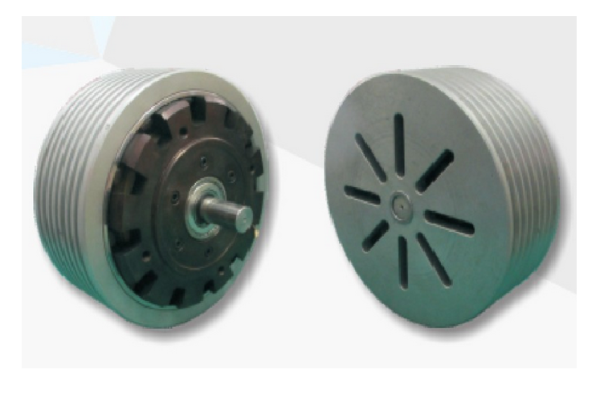

So, how does this wizardry actually work? Let’s peel back the curtain. At its core, a hysteresis brake consists of two primary components:

1. A stationary **Field Assembly**: This houses powerful electromagnets.

2. A rotating **Rotor Disc**: This is usually made from a special alloy with unique magnetic properties.

The magic happens without any physical contact. When electrical current flows through the windings in the field assembly, it generates a powerful magnetic field. As this invisible magnetic field penetrates the specially chosen rotor disc spinning within it, it induces magnetic poles within the disc material itself. Here's where the crucial \"hysteresis\" part comes in. The rotor material has a kind of magnetic \"memory\" or resistance. The magnetic domains within the disc material resist aligning perfectly with the external field. They lag behind. This internal friction, this resistance to change – **that's the hysteresis loss**.

This constant battle between the external magnetic field trying to align the domains and the material's inherent resistance causes energy to be dissipated as heat *within the rotor disc itself*. Crucially, this energy dissipation creates a drag force, a braking torque, that opposes the rotation. The beauty? The magnitude of this torque is directly proportional to the strength of the magnetic field generated by the current you apply. No touching, no grabbing, just pure magnetic influence creating a controllable drag.

Why does this matter so much? Because the benefits translate directly into superior performance and reliability in demanding applications:

1. **Silky Smooth, Jitter-Free Control 🌀:** Since there's NO physical contact, there's absolutely no stiction, no stick-slip effect, no chatter, and no vibration. The torque output is buttery smooth from the very first instant, enabling ultra-precise speed regulation, tension control, and positioning. Imagine controlling the deceleration of a high-speed spindle as gently as guiding a feather down. That’s hysteresis braking.

2. **Precision Torque Control Down to the MilliNewton 🎯:** The torque produced is directly and linearly proportional to the input current. Apply X milliamps, get precisely Y milliNewton-meters of torque. This repeatability and controllability are exceptional, making hysteresis brakes ideal for test stands requiring precise load simulation, delicate winding applications, and torque-limiting safety functions. You dictate the force with an electrical signal, and the brake obeys instantly and faithfully.

3. **Zero Wear \u0026 Virtually Infinite Life ⏳:** No contact means no friction, and no friction means no wear on the primary braking components. The rotor disc spins freely within an air gap. Barring catastrophic failure or bearing wear (which are common to *any* rotating device), the core braking mechanism itself essentially lasts forever. This translates to dramatically lower maintenance costs, zero downtime for brake pad replacement, and incredible reliability over the long haul. Think decades, not months.

4. **Clean Operation, No Dust, No Debris 🌱:** No rubbing parts means no generation of brake dust, metal particles, or other contaminants. This is absolutely critical in cleanroom environments (semiconductors, pharmaceuticals, medical device manufacturing), food and beverage processing, textile production where lint is a nightmare, and any application where contamination is unacceptable. Your process stays pristine.

5. **Instantaneous Response \u0026 Wide Speed Range ⚡:** Electromagnetics are fast! The braking torque responds nearly instantly to changes in the input current. Whether your rotor is spinning at 10,000 RPM or crawling at 10 RPM, the hysteresis brake delivers consistent, controllable torque. They work beautifully across exceptionally wide speed ranges, often down to true zero speed, where traditional friction brakes lose effectiveness. Torque control isn't dependent on speed.

6. **Inherently Cool Running (Relatively) ❄️:** While heat *is* generated within the rotor disc due to hysteresis losses (and to a lesser extent, eddy currents), this heat is dissipated effectively through the rotor's rotation and often aided by fins or forced air cooling. Crucially, there are no friction hot spots. With proper sizing and cooling, hysteresis brakes manage heat predictably, avoiding the thermal fade issues common in friction brakes under sustained load.

7. **Quiet Operation 🤫:** Silence is golden, especially in labs, medical settings, or high-end consumer applications. The absence of physical contact means hysteresis brakes operate remarkably quietly – often the dominant sound is just the whirring of the rotor itself or cooling fans, not the harsh grating or squealing of friction.

**Where Does This Hidden Hero Shine? Real-World Applications:**

The unique advantages of hysteresis brakes make them indispensable across a vast spectrum of industries:

* **Precision Manufacturing \u0026 Automation 🤖:** Robotic arm control, spindle braking for CNC machining centers (especially for tool changers and precision stopping), indexing tables, wire bonders, semiconductor wafer handling, delicate assembly processes. Smooth, precise stops and torque control are paramount.

* **Textile, Wire \u0026 Cable Production 🧵:** The king of tension control applications. Hysteresis brakes (and their clutch counterparts) provide the absolute gold standard for maintaining consistent, adjustable tension on yarns, threads, wires, cables, fibers, and films during winding, unwinding, spooling, coating, and printing processes. Imagine controlling the tension on a human hair-thin optical fiber at hundreds of meters per minute – hysteresis makes it possible.

* **Testing \u0026 Simulation Laboratories 🧪:** Dynamometers for engine, motor, and transmission testing; material fatigue testers; life cycle testers; torque calibration equipment. The ability to apply precise, repeatable, and programmable loads without wear is invaluable. Simulating years of real-world loading in accelerated tests demands this reliability.

* **Packaging Machinery 📦:** Controlling the speed and tension on webs of plastic film, foil, labels, and paper during high-speed filling, sealing, and cutting operations. Consistent tension prevents wrinkles, tears, and misalignment. The cleanliness is a huge bonus near food and pharmaceutical products.

* **Aerospace \u0026 Defense ✈️:** Flight control surface actuators, missile guidance systems, gimbal systems for sensors and optics, satellite component testing, antenna positioning. Reliability, precision, and lack of maintenance are critical in these high-stakes environments.

* **Medical \u0026 Life Sciences 🏥:** Surgical robots requiring tremor-free precision, diagnostic equipment like centrifuges and sample handlers, drug discovery automation, prosthetic limb actuators, MRI component positioning. The smoothness, precision, and cleanliness are non-negotiable.

* **Consumer Electronics \u0026 Office Equipment 📠:** High-end camera lens focus mechanisms, precision paper feed mechanisms in printers and copiers, tape drives, turntables. Delivering quiet, smooth, and reliable motion in compact spaces.

**Beyond the Basics: Understanding Key Considerations**

While hysteresis brakes are phenomenal tools, choosing the right one requires understanding your specific needs:

* **Torque Range:** Hysteresis brakes are available covering an enormous range, from miniature units delivering fractions of an ounce-inch for delicate instruments, right up to industrial powerhouses handling hundreds of pound-feet. Matching the brake's continuous and peak torque capability to your application is fundamental. Over-sizing wastes energy and requires more cooling; under-sizing leads to overheating and failure.

* **Cooling is Crucial:** Remember, all the braking energy converts to heat *inside* the rotor. While they handle this well, sufficient cooling (airflow, fins, sometimes even liquid cooling for very high-power applications) is essential for sustained operation at high torque levels. Pay close attention to the thermal capacity and duty cycle specs.

* **Control Electronics:** Since torque is directly controlled by current, you need a suitable electronic controller. This can range from a simple adjustable DC power supply for basic constant-torque applications to sophisticated servo amplifiers offering precise programmable torque profiles, dynamic control, and integration with PLCs or motion controllers. The brake is only as good as the control signal driving it.

* **Hysteresis vs. Eddy Current (Often Confused!):** It's easy to mix these up, as both are non-contact magnetic brakes. The key difference lies in the rotor material and the dominant loss mechanism:

* **Hysteresis Brake:** Uses a special magnetically \"hard\" rotor alloy (like Cobalt Iron). Torque is primarily generated by the *hysteresis loss* within the rotor material (domain flipping resistance), which provides torque even at zero speed. Torque is proportional to *current* and largely *independent of speed*.

* **Eddy Current Brake:** Uses a highly conductive non-magnetic rotor (like Copper or Aluminum). Torque is generated by *eddy currents* induced in the rotor, which create their own opposing magnetic field. Torque is proportional to *speed* and *current squared*. It provides minimal torque at low speeds and requires significant speed to generate useful braking force.

Understanding this distinction is vital for selecting the right technology.

* **Integration:** Consider mounting style (flange, shaft, foot), shaft size and keyway, electrical connections, and feedback options (some include tachometers for speed sensing). Ensure compatibility with your mechanical design and control system.

**The Future is Magnetic: Why Hysteresis Brakes Are More Relevant Than Ever**

As industries push towards ever-greater precision, miniaturization, automation, and sustainability, the inherent advantages of hysteresis technology become increasingly compelling:

* **The Rise of Robotics \u0026 Cobots:** The demand for smoother, safer, more precise robotic movement, especially in collaborative environments, aligns perfectly with hysteresis braking's strengths for joint control and safe torque limiting.

* **Demands for Cleaner Manufacturing:** Stricter regulations and quality standards in pharma, food, and electronics continuously drive the adoption of non-contaminating technologies like hysteresis brakes.

* **Miniaturization:** The ability to generate significant, controllable torque in very compact packages is crucial for medical devices, portable electronics, and advanced instrumentation. Hysteresis technology scales down beautifully.

* **Sustainability \u0026 TCO:** While the initial cost might be higher than some friction brakes, the virtually infinite service life, elimination of consumable parts (pads, linings), reduction in maintenance labor, and prevention of downtime make the Total Cost of Ownership (TCO) highly attractive over the equipment's lifespan. Less waste, longer life = greener engineering.

* **Advanced Materials and Control:** Ongoing developments in magnetic materials promise even higher torque densities and better thermal performance. Coupled with increasingly sophisticated, affordable digital controllers, hysteresis brakes are becoming even more flexible and powerful.

**Choosing Your Precision Partner: Beyond the Spec Sheet**

Selecting the right hysteresis brake isn't just about picking the highest torque rating. It's about partnering with an expert. Look for manufacturers and suppliers who:

* **Offer Deep Application Engineering Support:** They should ask detailed questions about your specific needs – torque profiles, duty cycles, speeds, cooling environment, control setup, integration challenges.

* **Provide Comprehensive Data:** Detailed torque vs. current curves, thermal performance charts, speed limits, dimensional drawings, and CAD models are essential.

* **Have Proven Reliability \u0026 Quality:** Seek out manufacturers with strong reputations in demanding industries. Quality bearings and robust construction matter.

* **Offer Customization:** Standard units cover many needs, but sometimes a custom shaft size, special mounting, integrated feedback, or unique cooling solution is required. Find a partner who can accommodate this.

* **Deliver Global Support:** Ensure they can provide timely technical assistance and replacement parts where you operate.

**Unleash the Potential: The Quiet Revolution in Motion Control**

In a world obsessed with speed and power, the hysteresis brake stands as a testament to the power of precision, elegance, and silent efficiency. It’s a technology that doesn’t shout; it simply performs, reliably and exquisitely, day in and day out, making the impossible possible in countless applications that shape our modern world.

So, the next time you see a robot perform a flawless surgery, unwrap a perfectly sealed package, or hold a satellite steady in orbit, remember the hidden hero working behind the scenes. It might just be a humble piece of metal spinning within a magnetic field, but the hysteresis brake is a masterpiece of engineering physics, quietly revolutionizing the way we control motion, one precise, frictionless revolution at a time. Don't settle for the screech and wear of yesterday's technology. Embrace the silent power and enduring precision of hysteresis. Your application deserves nothing less. 🚀